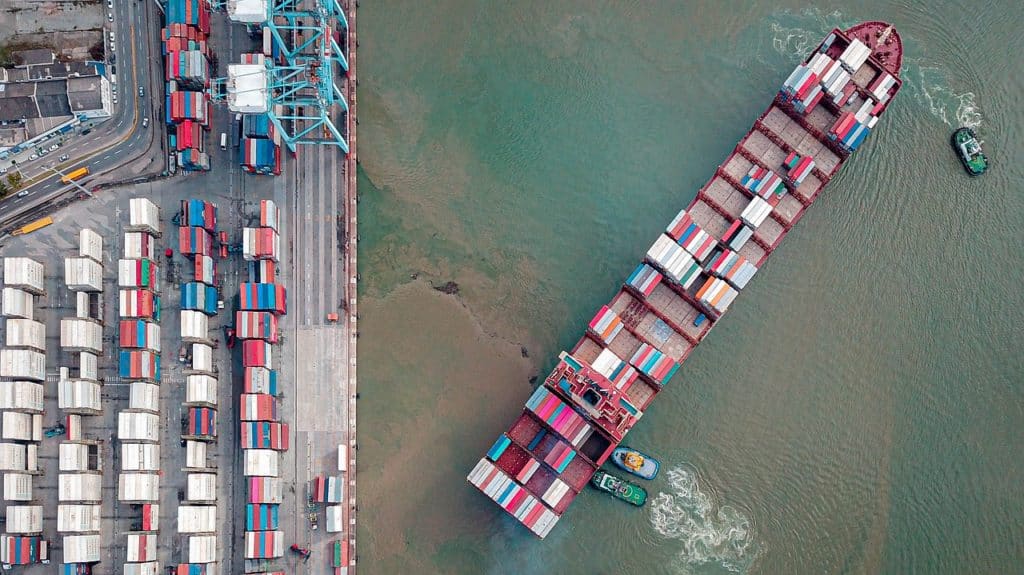

International cargo transfers, particularly in the marine industry, rely heavily on shipping containers.

These containers are available in conventional sizes and can be effectively carried over long distances and moved from one mode of transport to another without having to be opened.

Standardized containers have revolutionized the shipping and transportation industries, enabling the easy transfer of products through rail, road, and ship, since the containers readily fit into many modes of transport.

Container standardization has aided in increasing efficiency and economies of scale when shipping the approximately $3 trillion worth of goods that passes through our transportation networks each year, from aerosol cans to zebras!

Shipping containers serve as temporary storage for your products while they are en route. It’s the container freight railway, and you’re the container train.

Container shipping travel in conjunction with the cargo and the cargo is transported to the new place through container lading and axles.

This article will explain what a shipping container is, how do shipping containers work, what are the different kinds of shipping containers, the prices associated with shipping containers, and how to determine the size of your shipping container!

1. What Are Shipping Containers?

Contrary to popular belief, shipping containers are a very recent mode of transport for products, dating back just around 50 years. It’s hard to believe, but shipping containers have only been around for nearly 50 years as a means of transporting products.

And there is a very good reason why they’ve become so popular.

The usage of shipping containers began in 1956, when an American trucking entrepreneur, Malcolm McLean, transported trailer vans from New Jersey to Texas on a renovated tankship.

McLean’s inspiration for the containers stemmed from his attempts to cut costs in his own trucking business.

On a rebuilt tank ship from New Jersey to Texas, American trucking entrepreneur Malcolm McLean first used shipping containers. Prior to the widespread usage of shipping containers, the cargo was kept in temporary warehouses at shipping ports before the arrival of a ship.

The goods were then loaded onto the ships and stowed in their cartons and bags. An inefficient and unsafe method of transporting products aboard a ship was clearly evident, since it took a long time, required a lot of manpower, and could easily harm commodities that were exposed.

A week or more may be required to complete all of the paperwork involved in offloading such a large shipment at both ends of the journey. It would also take longer to unload the goods from the ship, convey them to the railway station, and risk damage, theft, or loss to the items again if the cargo needed to be transferred to a train.

Not only were there unnecessary delays when goods were not readily accessible and ready for installation, but even though there were established rules to avoid this, certain items could be misplaced or lost en route.

The companies’ responsibility was to load and unload the goods, but it would be an undue inconvenience to the companies if damage or loss occurred in shipping their products by sea.

Furthermore, if one were to calculate how much time it took for the cargoes to reach their destinations, a vessel’s sea trial was more than just two weeks.

2. Uses of Shipping Containers

Shipping containers are often utilized as additional storage areas, which may be readily adapted with doors, windows, and locks to offer additional illumination and security. They are leak-proof and durable, making them ideal for outdoor usage in any condition.

Additionally, shipping containers are often utilized as sheds, granny flats, and workshop structures. A shipping container pool is generating even more interest in a shipping container pool.

However, there is a lot of movement in the architectural industry right now toward designing with shipping containers and recycling them.

To learn about further applications for container transportation, continue reading below!

Amphitheaters

The trend of converting shipping containers into open-air theaters or bistros is on the rise. The usage of shipping containers in this way is limited, but it provides a unique entertainment venue for people to congregate in warm weather.

Schools

When building a typical school building is out of reach for certain regions of the globe, shipping containers are often employed as an alternative solution. A large educational institution may be divided into individual classes by using many containers in the same location.

Restaurants

Shipped containers may also be used as restaurants, especially in small spaces, to give a more conventional dining experience. Restaurants made from shipping containers include SnackBox in Times Square in New York City and MuvBox in Montreal, Canada.

Swimming Pools

Despite the fact that it is not as prevalent as some of the other applications, some shipping containers have been converted into swimming pools for individual houses or whole neighborhoods.

Because of their long-lasting construction and depth, some of the bigger shipping containers make great swimming pool enclosures.

Laboratories

In order to be utilized as testing labs for both educational and medical reasons, shipping containers of a suitable size and with sufficient space should be employed. There were even a number of the COVID-19 mobile testing units, which were constructed from repurposed shipping containers.

These comprised labs for interpreting test results and testing clinics with fully equipped examination rooms, among other amenities.

Homes

Huge, comfortable residences may be built out of a large number of shipping containers.

Shipping containers have even been used to build whole villages. Solar panels may be installed on the flat roofs of many of these buildings, making them more environmentally friendly.

Offices

It’s another imaginative method to take advantage of possible space constraints by using shipping containers as offices. Shipping containers have been transformed into offices. They may really be extremely useful and roomy when built in a stacked fashion.

Hospitals for the Injured

The utilization of shipping containers as emergency centers is on the rise. COVID-19 pandemic has seen shipping containers used as both testing and immunization facilities.

In response to the rising demand for COVID testing and immunizations, shipping containers were put in parking lots of shopping malls and pharmacies.

Toilets That Can Be Taken Anywhere

Containers used as temporary toilets are common. Portable toilets like this may assist ensure good sanitation and hygiene. Special events and outdoor locations are common places where shipping containers are utilized this way.

Stores

There’s a new craze in retail: selling goods out of cargo containers! A new shopping experience may be provided in metropolitan centers and other regions where there is not enough room for permanent buildings if shipping containers are positioned horizontally.

Studios

Shipping containers are becoming more popular as workplaces for artists and creatives. The containers may serve as an art gallery that can be visited by the public with pieces of art on display, allowing for a large studio area.

3. Different Kinds of Shipping Containers

Dry Storage Shipping Containers

Dry containers are a sort of ordinary shipping or cargo container that is used to transport dry goods that are not sensitive to temperature changes.

However, there are also 20-foot variations available. They are normally available in 40-foot sizes. The containers are made of heavy-gauge steel that can withstand wind, rain, and seawater.

There are several instances when you may design a dry container to include additional security measures or features for specific cargoes.

The shipping containers used for international transportation are built to resist the adverse weather conditions that they encounter on their journeys. Containers are made of high-quality steel and are completely wind- and water-tight.

They are equipped with two doors that are very well sealed.

A cargo container is dependable and long-lasting, and it will guarantee that the things housed within remain dry and in good shape. Shipping containers in the 20ft and 40ft lengths are the most popular size choices available.

Flat Racks Shipping Containers

Using a flat rack container, you may transport or store goods that have a unique dimension. The container is flat, as implied by its name, and goods may be loaded from either the sides or the top of the container.

Trucks, yachts, enormous vehicles, yachts, cranes, gas turbines, ship propellers, turbines, large engines, heavy machinery, and other types of cargo are often placed into flat rack containers, with the exception of a few exceptions.

These have foldable sides that can be folded, making them excellent for transporting boats, equipment, and automobiles.

Open Side Containers

A side opening container, also known as an open side container, is a shipping container that, in addition to the usual, locked double doors positioned on one end, features an extra set of bi-fold doors on one of the longer sides, which may be opened from the outside.

For starters, these containers make it simpler to load and unload specific kinds of goods than traditional shipping containers.

When using normal end-wall doors, you must carefully arrange your loading procedure in order to ensure that you and your employees can access critical cargo as rapidly as possible.

Furthermore, when dealing with a huge piece of merchandise that is buried deep inside a container, accessing and unloading it might be difficult, especially in an emergency scenario.

It may be necessary for you to remove all of the goods from your storage space between it and your entryway.

By enabling you to reach the center or back of a shipping container without having to dig through to your desired goods from the front, side opening containers alleviate this difficulty.

When you have an item on the other side of a container from where you want to open one of its side doors, the worst-case situation is that you are just 8 feet or less away from your target item — a much smaller distance to go than anything 20 to 40 feet away within a container.

Open Top Shipping Containers

Open top containers are those that feature an open top that is covered by a tarp rather than a solid roof. This allows for the loading of big cargo, such as lumber and scrap metal, from the top of the ship.

Open top containers, like closed containers, are often equipped with end doors to provide for more flexibility during loading and unloading.

Large, bulky goods cannot be carried by normal containers, hence this facility was created expressly for that purpose.

The container may also be entered by doors on each end of the container, which enables typical cargo to pass through.

The majority of containers are made of steel to give structural strength despite the fact that they have a discontinuity at the top. Reinforcements run along all four sides of the structure to maintain it stiff and to sustain weights coming from all directions.

The cover on top and the doors may be secured, and the doors are also shut by customs officials when a ship arrives at a port.

While other containers are difficult to tamper with because of the seal made on the locks, sealing open-top units presents an extra barrier.

As a result, heavy-duty coverings are used, which are held in place by clamp locks that are incapable of being opened without the use of a particular instrument.

Additionally, while in transportation, these containers are closely watched to ensure that no theft or damage occurs to the unit.

Unloading and loading procedures are performed in a manner comparable to those of a standard shipping container.

Spreader cranes are used to raise the unit into position, while container stackers are utilized to place the containers inside the yard.

The majority of the time, the goods inside the container fit well within the container dimensions, and the tarpaulin stays horizontal. In such circumstances, the container may be stacked underneath other units without causing any structural issues to the structure.

If, on the other hand, the cargo is enormous and bulky and does not fit within the container, then a piece of it will protrude over the container edges.

Stacking the container is not possible in such situations. Container units of this kind are maintained in a separate place during shipping in order to prevent damage to the containers themselves.

Similar to this, open-top containers are stored in a distinct position at the container yard to prevent them from being accidentally stacked.

It is only forklifts or vertical stacking cranes that can be used to move over-the-shoulder (OT) units with cargo that protrudes over the roof.

Refrigerated Shipping Containers

As a result of technological advancements, we now have specialized equipment, such as refrigerated containers, available. Reefers are another term for these vessels.

These are specifically built for temperature-sensitive cargoes like fruits, vegetables, meat, and other perishable items.

Refrigerated containers enable you to regulate the temperature of your goods to the exact degree you require. This helps to keep the interior temperature under control.

This guarantees that the cargo is shielded from the extreme temperatures found outside the container. Refrigerated containers are capable of controlling temperatures ranging from -65 degrees Celsius (-85 degrees Fahrenheit) to 40 degrees Celsius (104 degrees Fahrenheit).

Pricing is a crucial consideration when considering whether to hire a refrigerated shipping container or not.

However, this should not be the only factor to take into account. At the end of the day, you should be able to get the container that you need in order to carry your products securely.

4. Benefits of Using Shipping Containers

Flexibility

Shipping containers can carry a wide range of items, ranging from food grains and food products to machinery and other heavy equipment. There are varieties of containers that are flexible to ship such as the OOG.

The transportation of out-of-gauge freight (OOG) is made simple by the use of flatbeds or platform containers.

OOG cargo refers to cargo that is of atypical sizes and shapes and thus does not fit into standard shipping containers or containers of a standard size and form.

Reefers (Refrigerated Containers) are specially built containers that are used to transport things that are sensitive to temperature fluctuations, such as pharmaceutical medications and perishable food items.

The typical configuration is an insulated container that is equipped with a portable refrigeration unit to keep the food fresh longer. The temperature within a refrigerated container may be adjusted to meet the needs of the object that it is transporting, depending on its design.

Flexible tanks are strong containers that can be loaded with any non-hazardous liquid cargo for transport. The bag within the tank is huge, resilient, and flexible, so it can be filled with almost anything.

A flexible tank is a container that is used to convey liquid cargo in bulk. Examples of such liquid cargo include wines, latex, edible oils, and other similar liquids.

Easy Handling

A shipment consists of one or more shipping containers that are indivisible units. Each registered container is assigned a unique identification number that makes it simple to monitor and identify during the trip.

It is used by a variety of parties, including the shipper, the recipient, ports, and customs officials, among others, in order to verify the contents of a container.

Quick Transportation

Transshipment times have been dramatically decreased as a result of the introduction of larger and more powerful cargo ships, as well as contemporary container handling technology. In today’s world, loading and unloading are more efficient, both at ports and in new warehouses.

Material Handling Equipment (MHE) that is standardized makes it simpler to manage cargo containers that are arriving from and departing from various regions of the globe.

Efficiency as a Function of Scale

According to some estimates, the cost of shipping products via container is 20 to 25 times less expensive than the cost of transporting the same commodities as loose bulk or LCL. Containerization has reduced the importance of transportation costs in the price of products by a significant margin.

Economies of scale play a significant role in this situation. In general, economies of scale refer to the benefit that businesses get as a consequence of manufacturing or trading in large quantities.

Durability

A shipping container may last anywhere from 10 to 25 years, depending on how it is used. Containers are often utilized for storage or transformed into residential quarters after they have been condemned as being unfit for human habitation.

Storage warehouses and distributors often employ empty containers as temporary storage space, particularly when their own storage facility has surpassed its limit.

Containers may be put wherever in the warehouse yard that is convenient for the customer. It offers firms temporary and flexible storage space when they want it.

The concept of repurposing and using existing shipping containers into dwelling accommodations is becoming more popular across the globe.

When done effectively and artistically, they are rather affordable to put up while also being visually pleasing and fashionable.

Safety and Security

Containers used for intermodal transportation are safe and secure. These heavy-duty containers are walled on all five sides, with the exception of one end, which has double doors.

These double doors are equipped with two lock rods on each side, which are used to lock and seal the container, making it secure and tamper-resistant.

5. Disadvantages of Shipping Containers

Constraints of Space

Containers, whether they are loaded with goods or are empty, take up a lot of room aboard the ship.

Container terminals must have adequate stacking room to handle the large number of containers that come in and out of them. Containers that must be removed from a stack first must not be placed near the bottom of the pile.

The most up-to-date container handling equipment and other infrastructure must be in place in order to guarantee that cargo ships arrive at their ports in the shortest amount of time. A container port, in addition to having a favorable location, must take all of these factors into mind.

Infrastructure-Related Expenses

The most recent dockside gantry cranes and associated terminal equipment were purchased for several million dollars in the United States. Leading sports and terminals are those who are able to make these expenditures while also keeping their equipment up to date with the latest technological advancements.

While wealthier countries can afford to make such expenditures, developing countries may find it challenging to stay up with the competition.

Failure in the Container Management System

The prompt receiving and processing of information are critical in the management of containerized freight. A good terminal management software program guarantees that all of the information required for the proper operation of a terminal is managed effectively.

Cutting shortcuts in this area might have severe results.

Empty containers are being repositioned

Containers that arrive at their destination with goods are emptied and finally transported to a stack designated for empty containers at the port of departure.

Shipping firms need that their empty containers be readily accessible in areas where there is a demand for them. As a result, empties (empty containers) must be moved to their final destinations in a timely way to avoid accumulating.

It is important to note that a container, whether it is full or empty, needs the same amount of space, both during storage and during transshipment and distribution.

If empty containers are not transferred from empty container yards to locations where they may be put to use, there will be a demand-supply mismatch, which will result in a scarcity of containers for shipping in the future.

Shipping corporations spend a lot of money to reposition their empty containers, which costs a lot of money.

Smuggling

Containers are used to smuggle contraband, such as weaponry, narcotics, and even people trafficking, over international borders.

Customs agencies across the globe check containers at random, which is standard practice. It is probable that contraband will make its way through the system from time to time.

In addition to tip-offs, irregular paperwork, suspect patterns of shipping products, and other factors, the authorities may check specific containers for a variety of reasons.

X-ray scanners that can scan containers are used by customs officials in industrialized nations.

However, despite the negative aspects, analysts predict that containerized freight would expand at a pace of 3 – 4%each year over the next three years.

This is great news for the cargo shipping sector, which suffered a significant setback last year as a result of the Coronavirus epidemic.

6. Shipping Containers and Their Prices

Pricing is one of the most significant elements to consider when shipping products, but it’s also crucial to understand the roles and responsibilities of the consignee (shipper/buyer) and the distributor or seller in the process.

The cost of shipping containers varies based on many factors, including the geographic location, the condition of the container, modifications, size, and delivery costs.

It is dependent on the geographical area, the condition of the container, modifications, size, and the cost of delivery how much shipping containers cost differs from one another.

The cost of a used shipping container varies, but it is often in the region of $1500-$5000. New or one-trip shipping containers are often more costly, with prices ranging from $3000-$5000 on average.

For example, a simple bare-bones old container is far less expensive than a customized, new container with modifications. If you engage a contractor to handle all of the technical work, you could expect to pay between $50 and $150 per hour.

If you hire a contractor to complete your job, the overall cost of the project might be up to $15,000 or more. If you are handy and have previous building expertise, you could definitely do the project for less than $10,000.

Typically, corrugated steel, also known as COR-TEN, is used to construct the containers. The supply of containers, as well as their value, changes depending on the cost of steel.

Due to the fact that steel is extensively accessible and reasonably priced at the moment, more new shipping containers are being manufactured.

Because of the strong demand for shipping containers, the price has dropped, resulting in a more affordable alternative to traditional construction materials.

Factors Influencing the Cost of a Shipping Container

Condition

In general, depending on the condition, you may expect to pay between $1500 and $3000. Please keep in mind that price is subject to change depending on market circumstances in the shipping business; this is just an example.

They might be more or less costly depending on the market, but the price differences across condition kinds are usually stable.

Size

The cost of a shipping container increases in proportion to its size and varies from state to state. An average 40ft container costs between 20% To 30% more than a regular 20ft container, on average.

A used 40ft shipping container costs around $1700, whereas a new or one-trip 40ft shipping container costs approximately $3500.

For just around $200 more, you may convert your 40ft container to a “high cube.” In most areas, you will discover that the price to volume ratio for used shipping containers for sale is approximately 1:10 or better.

Customization and alterations

Adding extra choices such as a skylight, windows, a locking system, doors, ventilation, insulation, and so on can increase the overall cost of your home construction.

The greater the number of customizations you need, the higher the cost will be per item.

Volume

If you are purchasing more than one shipping container, many shipping container providers will typically offer a bulk discount rate, resulting in a lower cost per unit of shipping container purchased.

Delivery

The cost of delivering containers varies based on the number of containers being transported and the distance they must travel. The cost of a container increases in direct proportion to how far you are from a port.

A shipping container for residential or commercial use is far less expensive than the cost of a completed construction such as brick and mortar structures or the cost of constructing a house from the ground up in most cases.

These structures need the use of bigger and more costly foundations, as well as more intense work.

You will save money on human labor by using a cargo container to construct your structure. If appearances are not important to you, purchasing a new container may not be essential; instead, purchasing a secondhand container might save you money.

A new container, on the other hand, may be desirable, particularly if you are constructing a house and want to save money by not having to restore a used container.

Takeaways

Shipping containers are an essential aspect of the shipping industry’s supply chain. It is not only possible to utilize these massive storage containers to transport commodities across seas, but they may also be customized for a variety of other applications.

One of the various varieties of shipping containers available for customization to meet your specific demands as a temporary office or storage space is a good alternative for your company if you want an extra-strong, durable, and environmentally friendly solution.

0 Comments