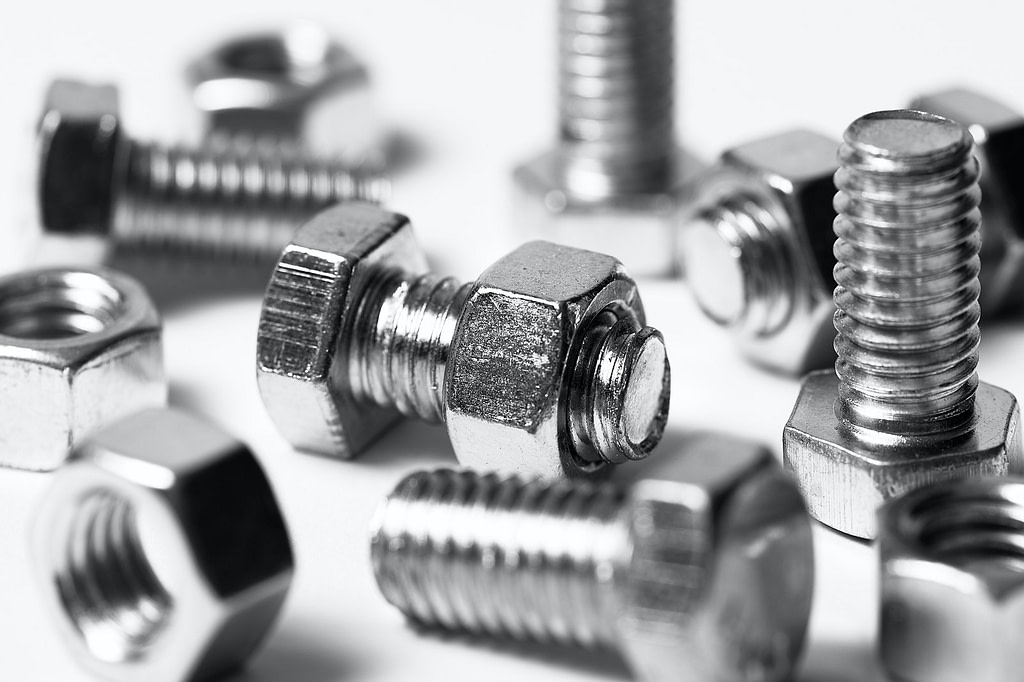

Machines are often connected together using fasteners, the most common of which being machine screws.

Machine screws are found in a wide range of equipment, from engines and appliances to industrial lathes and milling machines.

You’ll need to determine which screw is ideal for the task based on the work you want to perform.

While every kind of screw has a function, machine screws are ideal for home furniture hardware and materials such as electronics and appliances.

They are substantially different from other furniture screws, so let’s look at some of the distinctions between machine screws and bolts.

Our article is intended to provide you a comprehensive overview of machine screws, helping you in understanding what they are and the types of applications in which they are frequently utilized.

We’ll also go over the key distinctions between machine screws and bolts.

Continue reading to learn more!

1. What is a machine screw?

Machine screws are uniformly threaded screws with a nominal diameter of 1/4 inch or less that are meant to be threaded into equally threaded nuts or threaded holes in the components to which they are intended to attach.

Unlike other furniture accessories and materials like shelf support, and patio furniture, a machine screw is specifically intended to be used in a machine. It is inserted into a pre-cut hole and keeps the machine’s components connected.

Machine screws are made up of a head and a fully threaded shank.

The machine screw may be driven into a tapped hole with internal threading since the shank has external threading.

Machine screws have consistent threading that is the same size from top to bottom.

Advantages of machine screw

Machine screws are frequently chosen over bigger furniture screws of a similar size. They have a broader variety of uses due to their compact design.

Machine screws may be used to connect a wide variety of machines, objects, and surfaces.

Machine screws come in a variety of materials as well. Stainless steel is a widely utilized material in the manufacture of machine screws.

It is durable and long-lasting, with excellent resistance to rust and corrosion.

Another popular material used in the manufacture of machine screws is aluminum.

Like stainless steel, it protects against rusting and corrosion.

Aluminum machine screws are not as durable as stainless steel machine screws, but they are also lighter.

Aluminum machine screws may be chosen in cases where weight is an issue.

Many sourcing companies nowadays are providing high-quality machine screws that fit your needs. Do not hesitate to consult and get in touch with one as they can definitely help you with all that you need to know.

2. What is a bolt?

A bolt is a threaded shaft mechanical fastening. Bolts and screws are closely linked.

These fasteners are usually placed through two components that have aligned holes.

Furniture bolts outperform ordinary furniture screws and other fasteners in terms of holding strength.

Because of their threads, bolts may offer an unrivaled degree of gripping strength.

They do need the use of a nut and a washer for installation.

The washer distributes the load across a wider surface area, reducing wear and tear as well as the loosening of your bolt over time, while the nut holds the bolt in place.

Bolts, like screws, come in a variety of sizes and shapes. They may also be used with a variety of furniture materials, including metal, wood, and concrete.

To remove or install a bolt, a handheld or pneumatic wrench is required. Bolts, as opposed to screws, may be simpler to remove.

The advantage of a pneumatic wrench is that it produces much greater torque than a handheld instrument, making your work simpler.

The hex bolt is the most frequent kind of bolt.

The hexagonal form of the head provides flat surfaces for tools to impart torque during attaching.

For earlier bolts, an easier-to-manufacture square head was utilized, and this is still used today for applications requiring very high torque to be delivered with a wrench.

Advantage of bolts

Bolts have the highest holding strength and an unmatched degree of gripping power when compared to screws and other fasteners.

They need a nut and a washer for installation; the nut holds the bolt in position, while the washer helps to distribute the load across a wider surface area, reducing wear and tear.

The bolts are available in a variety of sizes and kinds, as well as a variety of materials ranging from metal to wood to concrete.

A bolt needs a handheld or pneumatic wrench to remove or install, and bolts may be simpler to remove than screws.

Since a pneumatic wrench delivers considerably greater torque than a handheld instrument, it simplifies your job.

3. Difference between machine screw and bolts

Machine screws and bolts may seem to be the same thing, but they are not. Bolts have a hex head, while machine screws have a slotted head.

Machine screws with slotted heads may be installed using a screwdriver, such as a Philips head or flat-heat screwdriver.

A machine screw may be installed by inserting a screwdriver into the slotted head and twisting it.

On the other way, you may remove a machine screw by rotating the screwdriver (counter-clockwise).

Bolts, on the other hand, are usually installed using a hex socket. They do not have a slotted head. Bolts, on the other hand, have a hex head that can only be used with a hex socket.

To install a bolt, slip a hex socket over the bolt’s head and turn it.

Another distinction between machine screws and bolts is their size.

When compared to other fasteners such as bolts, most machine screws are very tiny. Bolts come in a range of sizes, some of which are almost 2 inches long.

Machine screws, on the other hand, are often less than one inch in length. Longer machine screws are still available, although they are usually available in lower sizes than bolts.

Bolts are intended to be fitted with a corresponding nut. The bolt hole is not tapped because the bolt is driven in and secured and tightened with a nut at the rear of the material being attached.

As a result, a bolt will be longer than the width of the material on which it is used since it must extend through to the opposite side to screw into the nut.

When compared to fully threaded furniture screws, the unthreaded part of the bolt (which lies within the material) provides strength and makes it more resistant to shear pressures.

Bolts are typically tightened using a spanner or other instrument that holds the head while tightening the nut.

Bolts, on the other hand, maybe used in the same manner as screws are if they are put into threaded components.

This is a video of machine screws and bolts comparison.

If you are still clueless about what to get, you can always count on a trustworthy sourcing company near you.

4. Takeaways

Overall, the fastener is employed as a constraint for keeping things together or connecting to other objects, and the primary physical distinction between bolts and screws is that bolts have shanks without threads, while screws have threads all the way through.

A better approach to understand the distinction between bolts and screws is that screws are often used with tapped holes, while bolts are always equipped with nuts.

0 Comments